Download GCG’s RCS Checklist

Find out the steps you need to take to understand the monitoring requirements and to keep your employees safe

The Department of Natural Resources and Mines released a guideline in August 2017 for the management of Respirable Crystalline Silica (RCS) in Queensland Mineral Mines and Quarries (QGL02 – Guideline for Management of Respirable Crystalline Silica in Queensland Mineral Mines and Quarries).

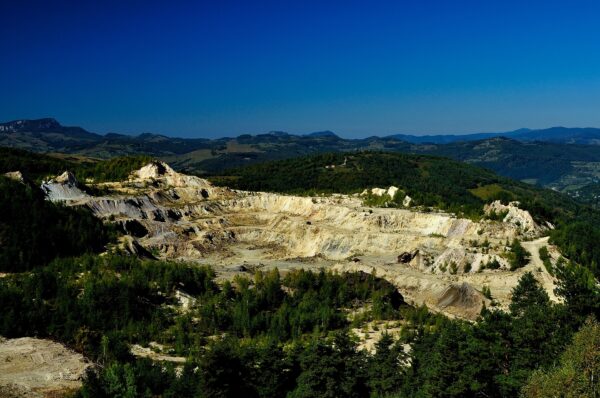

RCS occurs naturally and is a basic component of soil, sand & granite. A significant amount of silica is present in most rocks, clays, sands, gravel and shale. Quartz is easily the most common form of RCS present. The International Agency for Research on Cancer (IARC) has classified RCS as a Group 1 cancer-causing agent. This classification puts RCS alongside other airborne hazards such as asbestos, wood dust, welding fumes and cigarette smoke.

The Guideline covers the main requirements for occupational hygiene exposure monitoring that must be planned, programmed and conducted within Queensland Mineral Mines and Quarries. This is a fairly significant change in approach which has put a stricter framework in place for your occupational hygiene monitoring. Many of the occupational hygiene practice requirements were in place at GCG prior to the release of the guideline and we have responded those minor changes that affect us accordingly, to ensure our client’s compliance.

The Guideline includes requirements for the identification, assessment and control of RCS exposure to workers. Included within this are specifications on exposure monitoring that must be overseen by a competent “Occupational Hygienist”. Exposure monitoring must be undertaken by an “Occupational Hygiene Technician”, with minimum competency requirements now defined for both of these roles. In order to ensure our level of service is maintained, GCG has performed an internal gap analysis and are currently updating our systems.

If it looks familiar to you, that’s because the Guideline follows a similar framework to the requirements of the Department of Natural Resources and Mines Recognised Standard 14 – Monitoring Respirable dust in coal mines.

GCG has created a checklist for you to self-assess your compliance against the new guideline. If you have conducted occupational hygiene monitoring, some of the aspects may be familiar or already in place at your site.

Throughout the checklist, we have made minor adjustments to the terms used to simplify the scientific aspects of occupational hygiene. Please ensure you refer to the released guideline (found here) for the complete details in order to comply with the requirements, as the checklist should only be used as an initial tool for assistance and familiarisation.

For your reference, Mining and Quarrying activities that have a potential to generate dust with RCS content are:

Should you require any further assistance working out what this means for you, we would be delighted to help.

Feel free to contact us to talk with a Senior Occupational Hygiene Consultant.

Australia wide: 1300 424 474

Find out the steps you need to take to understand the monitoring requirements and to keep your employees safe